Location: Spacesavers Specialists Inc. Tualatin Oregon

Duration: Planning/Design – Jan. 2015 through Feb. 2016 Installation – Mar. 2016 through Aug. 2016

Client: Spacesaver Specialists

Key Project Contributors:

Jim McCord, Matt Reader, Tim Coulter, and Jason Moffett

OPPORTUNITY

Mobilize existing racking to gain capacity and provide a show piece for industrial clients.

SOLUTION

– Spacesaver ActivRac powered mobile shelving –

– Including 16,000 lb rail system –

– Increase pallet rack bays from 13 to 19 –

– Reduce footprint by nearly 1000 Sq. Ft. –

– Increase pallet capacity from 130 to 190 –

ActivRac - How It Works

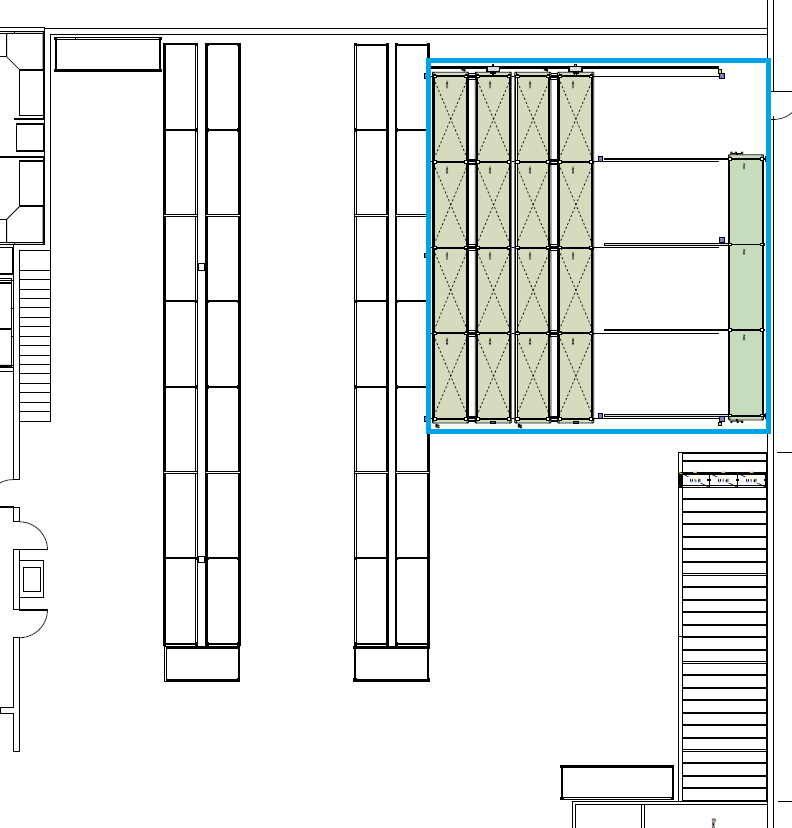

990 Square Feet Recovered to be Used as Flex Space

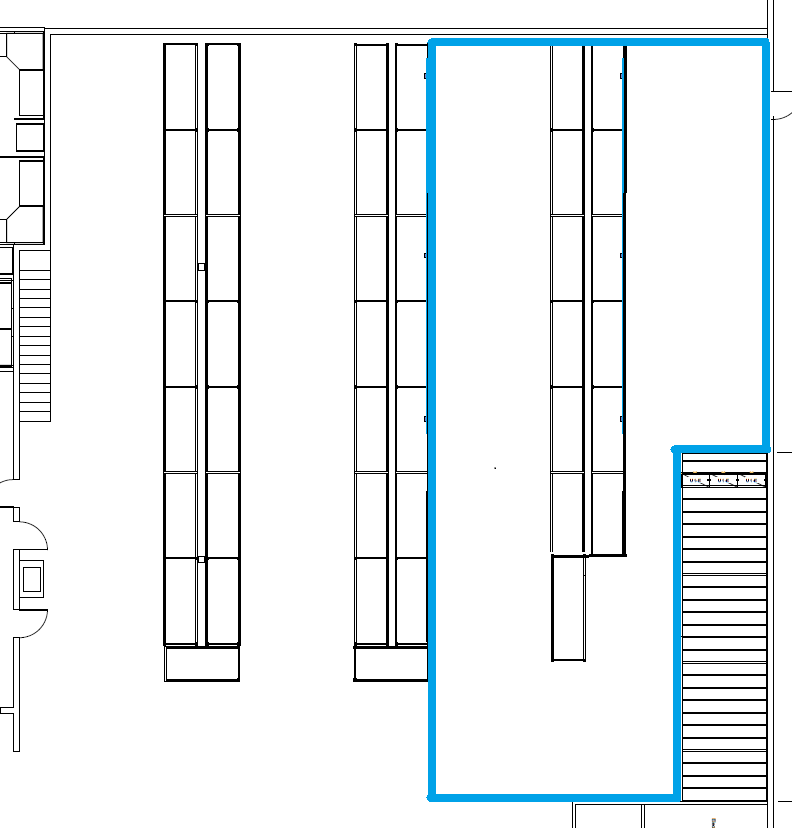

Old Features

13 Pallet Rack Bays

2458 Sq. Ft. Overall Footprint

Approximately 130 Pallets

New Features

19 Pallet Rack Bays

1468 Sq. Ft. Overall Footprint

Approximately 190 Pallets

Installation Process

First the existing rack is removed and will be reinstalled once carriages have been made.

Once pallet racks have been removed, we then have to cut troughs in the concrete where the guide rails will be installed.

Next we install one of two rails, 7,000 lb or 16,000 lb, depending on the support needed. Then epoxy rails in concrete troughs.

7,000 lb 16,000 lb

While the epoxy cures, Installation of the overhead electrical supply framework begins.

Once rails are set we move the ActivRak carriages in place for assembly.

After carriages are secure we reinstall the static pallet racking that was previously in its place. Once anchored it is now free to roll back and forth over the rail.

With carriages and pallet racks installed we then run electrical from the stanchion, through framework and to the motor.

Lastly we hook up power and place cover back over the stanchion. Once the system as been fully tested, we are free to load pallets on the 277,000 lb capacity mobile system.

Finished Installation

By the Numbers

– 277,000 Pounds Of Storage Weight Capacity –

– 190 Pallet Locations – 46% Increase –

– 60% Footprint Of Traditional Layout –

A Game Changer

Taking high density shelving capacities to the warehouse level, companies can massively reduce costs while easily maintaining a clean and highly organized space.